Resilient Impressions: The Role of Inkjet PP Papers Across Industries

In the dynamic landscape of printing technologies, the choice of paper is a critical factor that significantly influences the quality and resilience of printed materials. A notable advancement in this domain is the advent of Inkjet pp paper, celebrated for their exceptional durability and water-resistant properties. This article explores how these innovative papers have found applications across various industries, offering a winning combination of strength and resilience.

Durability Redefined:

Polypropylene, a versatile thermoplastic polymer, serves as the foundation for inkjet papers designed to go above and beyond traditional paper options in terms of durability. Unlike standard papers that can be susceptible to tearing, creasing, and yellowing over time, polypropylene-based papers boast a level of robustness that redefines expectations.

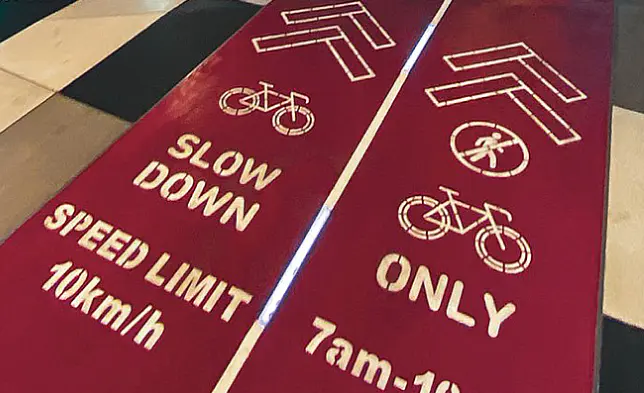

The enhanced durability of these papers makes them particularly well-suited for applications demanding resilience. Outdoor signage, banners, and marketing materials benefit immensely from polypropylene's ability to withstand wear and tear. Whether exposed to the elements or handled frequently, prints on polypropylene-based papers maintain their structural integrity, ensuring a longer lifespan compared to their conventional counterparts.

Water-Resistance as a Game-Changer:

A standout feature of Inkjet pp paper is their inherent water-resistant nature. Traditional paper, when exposed to moisture, often results in ink smudging and a compromised physical state. In contrast, polypropylene creates a protective barrier, repelling water and preserving the quality of the printed content.

This water-resistant quality introduces new possibilities for various applications. In photography, prints on polypropylene-based paper can endure accidental spills or humid conditions without sacrificing image quality. This resilience extends to outdoor uses, where the threat of rain, dew, or other weather elements no longer poses a risk to the longevity of printed materials.

Cross-Industry Applications:

Inkjet pp paper have found applications across diverse industries, owing to their durability and water-resistant characteristics. In the realm of advertising and marketing, businesses can confidently deploy promotional materials outdoors, knowing that prints will withstand exposure to rain, wind, or sunlight. This is particularly advantageous for events, trade shows, and outdoor campaigns where traditional paper might falter.

Do you know common Inkjet printing material?

Common Inkjet printing material can vary depending on the specific type of inkjet printer (e.g., aqueous, solvent, UV-curable) and the intended application. Here are some commonly used materials across different types of Inkjet printing material:

Aqueous Inkjet Printing:

Paper: Standard inkjet paper, photo paper (glossy, matte, satin). Canvas: For art and photo printing. Textiles: Cotton, silk, and other fabrics for textile printing. Transparencies: Clear sheets for overhead projections. Cardstock: Thick paper for business cards, invitations, etc.

Solvent Inkjet Printing:

Vinyl: Self-adhesive vinyl for stickers, decals, and signage. Banner Material: PVC or vinyl banners for outdoor advertising. Backlit Film: Translucent film for illuminated signs. Mesh Fabric: Used for large-format outdoor banners.

UV-Curable Inkjet Printing:

Plastic: Acrylic, polycarbonate, and other rigid or flexible plastics for signage and promotional items. Metal: Aluminum or other metals for durable outdoor signs. Glass: Used for printing on glass surfaces. Wood: Wooden surfaces for artistic prints or signage.

Dye-Sublimation Printing:Polyester Fabric: Dye-sublimation works best on polyester-based fabrics for clothing, banners, and soft signage. Ceramic: Sublimation can be used on coated ceramic surfaces for personalized items. Metal: Aluminum surfaces for creating metal prints through dye-sublimation.

3D Printing:

Various Plastics: PLA, ABS, PETG, and other thermoplastics for Fused Deposition Modeling (FDM) 3D printers. Resins: Liquid resins for stereolithography (SLA) and Digital Light Processing (DLP) 3D printers. Powders: Used in powder bed fusion technologies like Selective Laser Sintering (SLS).

Bioprinting:

Bioinks: Hydrogels containing living cells for 3D bioprinting applications. Always refer to the specific recommendations of your inkjet printer and the type of ink it uses when choosing materials. Additionally, ensure that the material is compatible with the intended application and environmental conditions (e.g., indoor vs. outdoor use).